Current topics for the Stanztec trade fair

24. March 2025

Save the Date: High-End Technologies at Stanztec 2026!

The 8th Stanztec international trade fair for stamping technology will open its doors at its traditional venue at the Congress Centrum in “gold city”…

24. September 2024

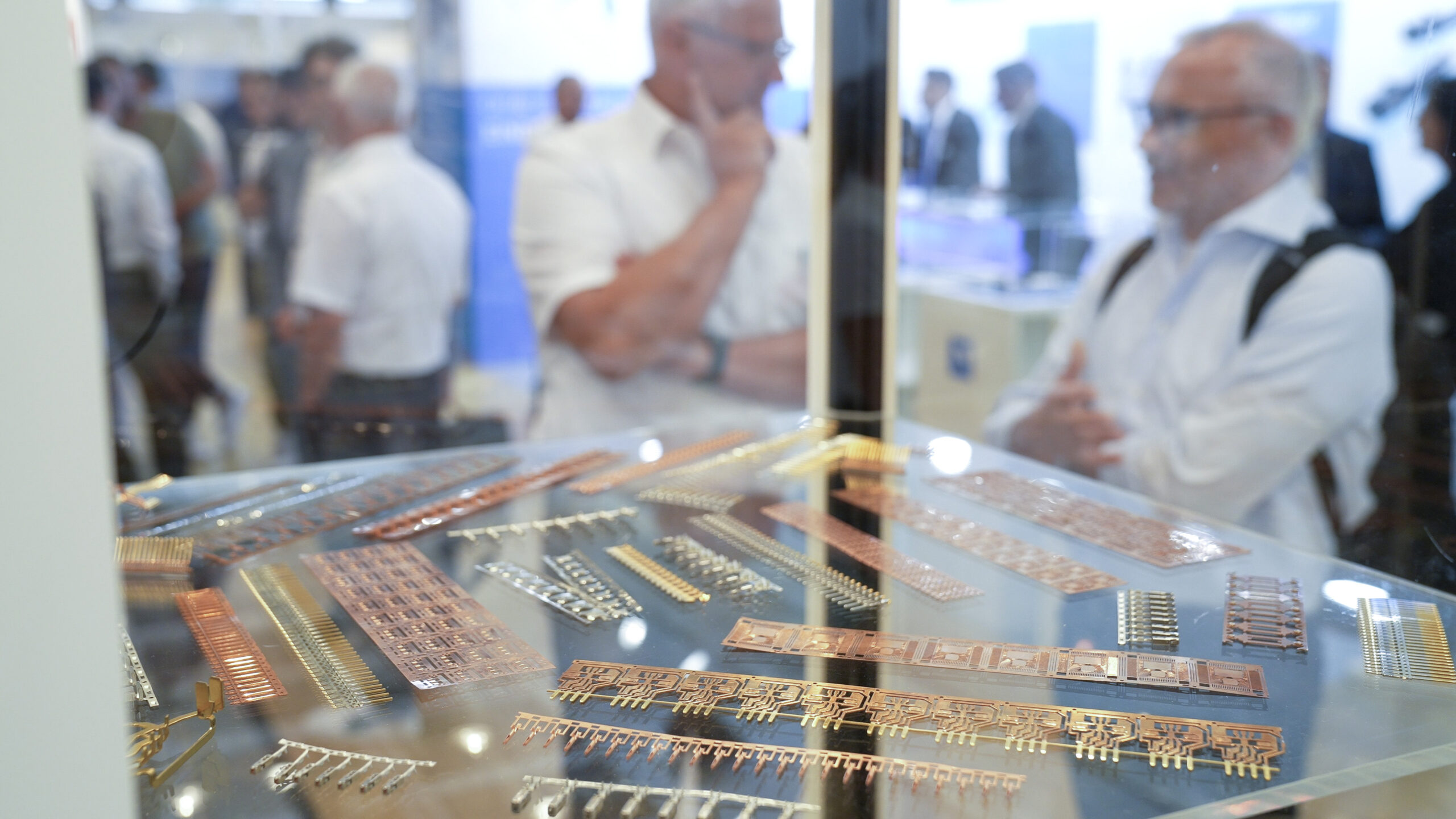

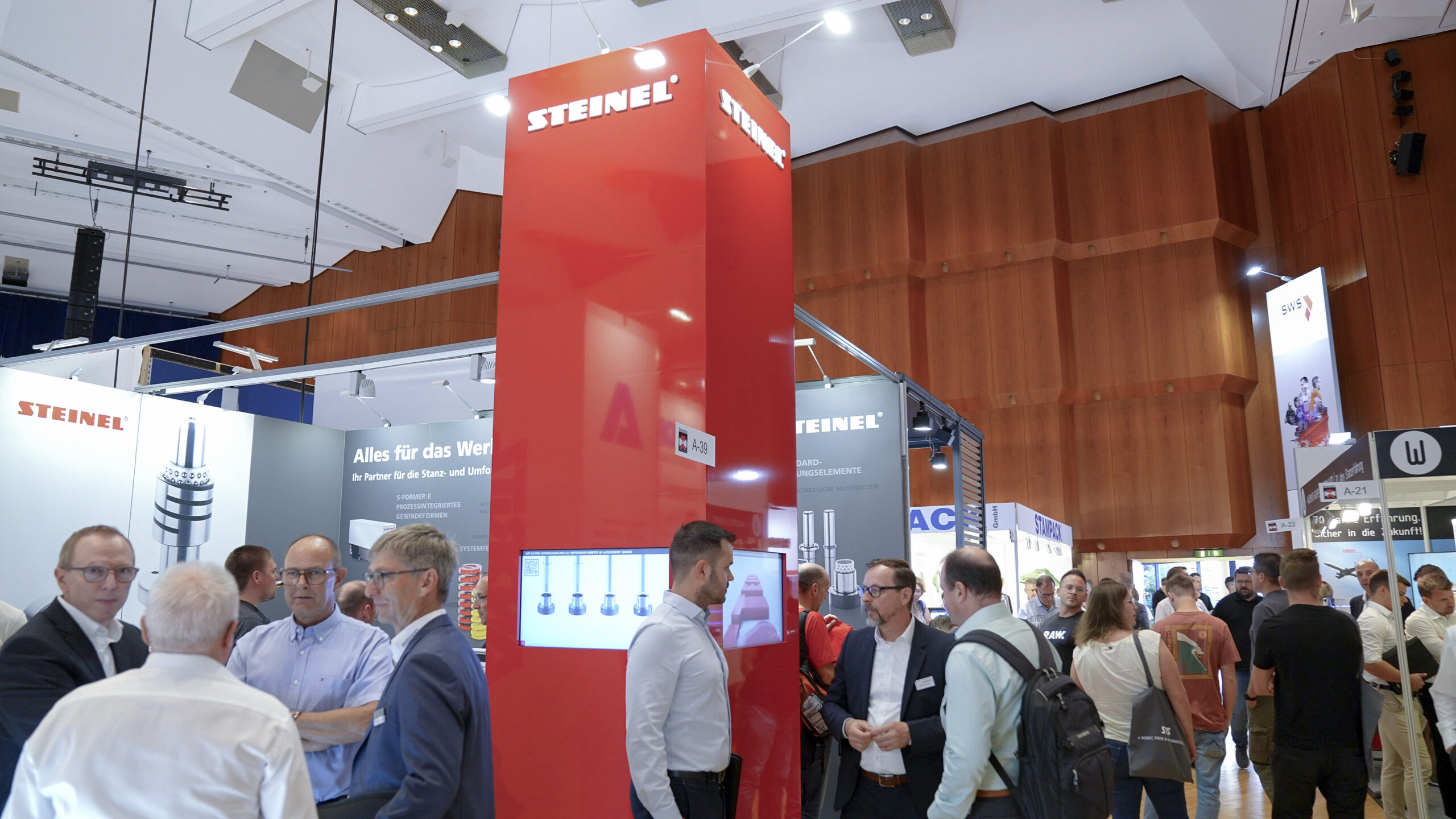

Brilliant! Technological highlights from Stanztec 2024

Stanztec 2024 once again set new standards in stamping and forming technology and presented brilliant innovations and technological advances. In our…

28. June 2024

A Brilliant Relaunch for Stanztec in 2024!

138 exhibitors and 3750 expert visitors from 27 countries celebrated cutting-edge stamping technologies on 3500 square metres of exhibition floor…

27. June 2024

Stanztec 2024 – Trade fair films “Statements & Scenes”

[borlabs-cookie id="youtube" type="content-blocker"][/borlabs-cookie] Day 3: Stanztec Statements & ScenesStamping technology…

25. June 2024

Expert meeting at CCP Pforzheim: Huge joy of meeting each other at Stanztec 2024

For the seventh time, the industry is addressing top topics relating to stamping and forming technology as part of the highly specialized Stanztec, a…

12. June 2024

Free digital edition of BLECH ‘Stanztec Special’

The free digital edition of BLECH ‘Stanztec Special’ offers you the opportunity to find out about exciting new products and innovations before the…

16. May 2024

Stanztec 2024: Expert Visitors Experience a Dazzling Array of High-End Technologies

Brillant stamping technologies – that’s what it’s all about at the 7th Stanztec trade fair for stamping technology at the Congress Centre in “gold…

6. February 2024

Eagerly Awaiting Brilliant Stamping Technologies

For the seventh time, the industry will deal with key topics covering all aspects of stamping and forming technology at the highly specialised…

13. December 2023

“Stanztec again at last!”

The stamping technology experts extend their invitation to the Stanztec trade fair for stamping technology in Pforzheim from the 25th through the…

29. March 2023

Expert Valley Looking Forward to Stanztec 2024!

Stanztec again at last! The seventh Stanztec trade fair for stamping technology is underway. The industry event will open its doors in Pforzheim from…

12. December 2022

60 years of Schall – 7th Stanztec – with exhibitor ANDRITZ Kaiser

[borlabs-cookie id="youtube" type="content-blocker"][/borlabs-cookie] In Schall’s anniversary year, we visit partners of…

22. June 2018

Exhibitors Praise Stanztec 2018

Exclusive Meeting Place for Stamping All-Rounders and Sheet Metal SpecialistsThe sixth Stanztec trade fair for stamping technology from 19 to 21 June…